Quality Assurance at J-Marcs Corp.

starts long before the metal

removal processes begin.

Beginning at the

quoting stages of a job, J-Marcs personnel perform

their duties in accordance to strict operating procedures including timely

and accurate estimating of price, delivery schedules, and terms and

conditions in order to ensure a smooth transaction with our customer.

Upon receipt of

an order, the job is scheduled into the shop in

accordance with the manufacturing time required to finish the

required to finish the

work as quoted.

This includes:

1) The timely

ordering of raw

material when

required --(much

of our work

involves customer

supplied castings).

2) Document

review to ensure

that specifications for a particular part haven’t changed for repeat orders.

3) Development of the most practical and economic routing for new

jobs and reviews of existing routings for previous jobs in order to verify

that the best methods will continue to be used.

4) The preparation

and staging of the shop production package including

work order, latest revision drawing with highlighted critical dimensions,

and necessary fixtures, tooling, and gages particular to the job.

5) Receiving

inspection including verification of size, alloy, certs (if

required), and count for commodity raw materials and the observation

of general surface appearance and count for customer supplied castings.

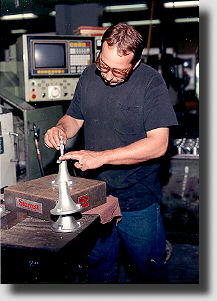

Using

conventional inspection tools regularly calibrated with

J-Marcs in-house calibration standards

along with custom made gages particular to the job, our highly versatile and skilled

machinists go to work. At-machine inspection is continuous and based on some of the

particulars of the job with 100% inspection routinely performed on first time jobs and

critical dimensions. As J-Marcs specializes in the precision machining of castings, our

machinists are well known for their timely resolution of defects inherent in the casting

process (such as inclusions) that affect the dimensional integrity of the finished

part--usually right at the machine with our customer’s engineers. calibration standards

along with custom made gages particular to the job, our highly versatile and skilled

machinists go to work. At-machine inspection is continuous and based on some of the

particulars of the job with 100% inspection routinely performed on first time jobs and

critical dimensions. As J-Marcs specializes in the precision machining of castings, our

machinists are well known for their timely resolution of defects inherent in the casting

process (such as inclusions) that affect the dimensional integrity of the finished

part--usually right at the machine with our customer’s engineers.

It all adds up....state-of-the art production and inspection

equipment,

careful attention to all of the up-front and in-process details of your

machining requirements, and a highly experienced group of skilled

machinists.....J-Marcs Machinery, Methods, and Manpower being

put to use to ensure the integrity of your products and reduce your

costs of quality. |