1) Quantities -

Single prototypes

to continuous

production runs.

2) Materials -

All metals (except

magnesium),

plastics. We

specialize in

cast aluminum

alloys, brass

alloys, steel, and

steel alloys.

3) CNC Turning

Diameters up to

20", Maximum

length 36",

Tolerances to

+/- .0005"

4) Manual

4) Manual

Turning -

Diameters up to

16", Maximum

length 60",

Tolerances

to+/-.0005"

5) Hard Turning

Diameters up to

7", Maximum

length 36",

Tolerances to

+/-.0002"

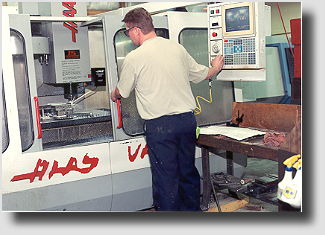

6) CNC Milling & Drilling

- Maximum workpiece size 20"x40"x16",

Tolerances to +/- .0005"

7) Manual Milling - Maximum workpiece size

20"x40"x10",

Tolerances to +/- .001" Hole Tolerances to +/- .0005"

8) Welding - Mig, Tig, Arc

9) Assembly - We maintain a dedicated

work area for the assembly

of multiple machined components including insert, sleeve, and bushing

pressing up to 150 tons.

10) Secondary - J-Marcs utilizes only

the highest quality sources for

the supply of secondary operations such as plating, black oxide and

other coatings, broaching, splining, heat treating, and others in

accordance with the requirements of our customers. All secondary

operations suppliers are located in the Greater Chicago area in close

proximity to our manufacturing plant.